Some of our solutions include:

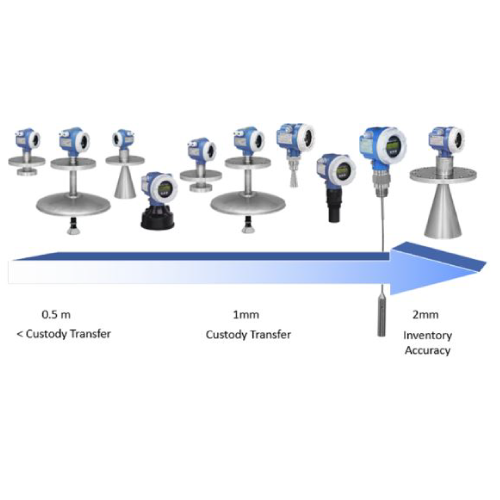

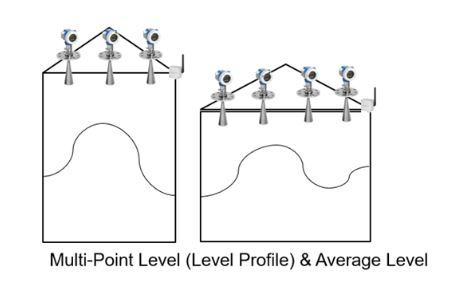

Free Space Radar and Guided Wave Radar for Continuous Level and in liquids - Time of Flight and FMCW

- Hydrocarbons such as crude oil; fuel including diesel, gasoline, jet A1, HFO, bunker C, LPG.

- Chemicals such as NaOH, H₂SO₄ , HCL, Nitric Acid, Ammonia, Urea, Methanol and Melamine.

- Hygienic applications such as soft drink, juice, water and milk.

- The rum industry such as alcohol, molasses, distillery wash and solvents.

- The brewing industry such as beer, wort, malt and hops.

- Boiler drum level

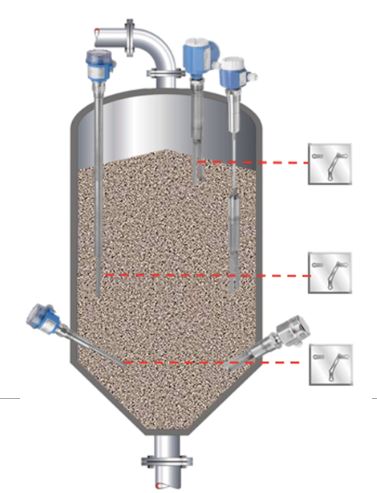

- Free Space Radar and Guided Wave Radar for Continuous Level in Solids - Time of Flight and FMCW

- Mining Industry, Aggregate, Cement, Gypsum, Clinker, Slurries, Alumina Oxide, Bauxite, Iron Ore and Direct Reduce Iron (DRI)

+1- 2mm Accuracy.

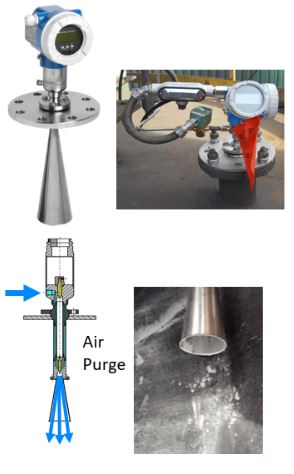

Frequency 26 GHz — Advantages:

- Independent of dust and filling noise.

- Narrow beam for narrow silos or for installation closer to the tank wall.

- Measuring range 70 m.

- Temperature up to 400 ° C.

- Pressure up to 16 bar.

- Air purge connection as standard.

- Top target positioner for positioning of the horn for best measurement.

- 2'd 4..20mA for monitoring of signal strength.

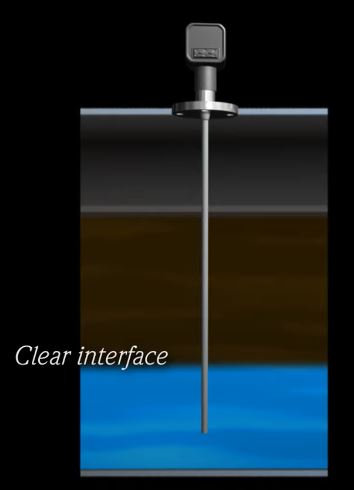

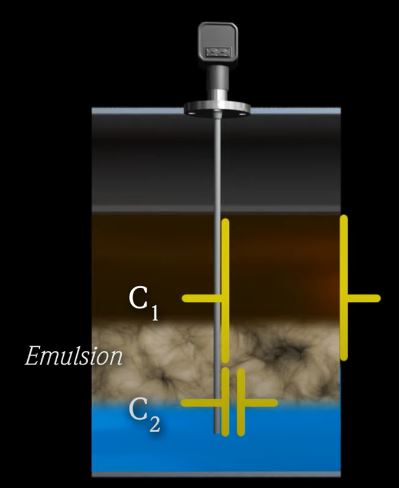

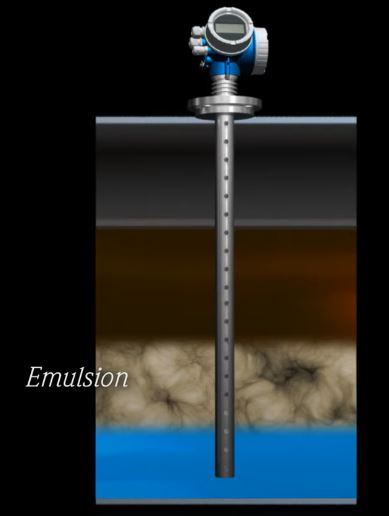

Guided Wave Radar for Continuous Level and Interface - Time of Flight and FMCW

- Wash tanks and separators - Interface such as Hydrocarbons and Water with Clear or Emulsion Interface.

Servo Gauges for Custody Transfer Measurement in Liquified Gases

- LPG, LNG and Ammonia

Ultrasonic for Continuous Level

- Water and Wastewater in open channels or tanks

- Aggregate and slurries

- Bleach

Capacitive for Point / Limit Level Detection, Continuous Level and Interface

- Water

- Filler bowl in bottling hall

- Food such as flour and rice

-

Wash tanks and separators - Interface such as hydrocarbons and water with clear or emulsion interface

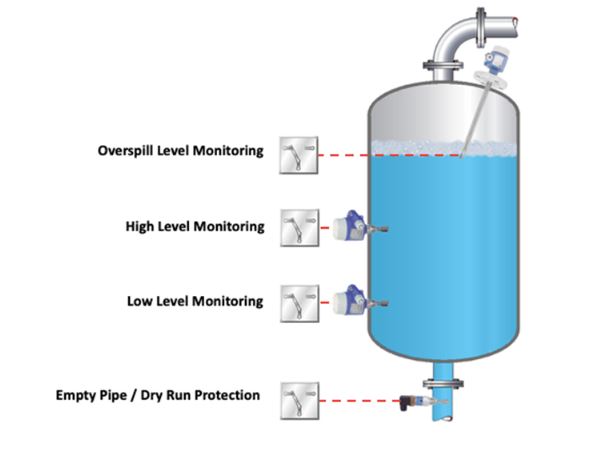

Vibronic for Point / Limit Level Detection

- Hydrocarbons such as crude oil; fuel including diesel, gasoline, jet A1, HFO, bunker C, LPG.

- Chemicals such as NaOH, H₂SO₄ , HCL, Nitric Acid, Ammonia, Urea, Methanol and Melamine.

- Hygienic applications such as soft drinks, juice, water, and milk.

- The rum industry such as alcohol, molasses, distillery wash and solvents.

- The brewing industry such as beer, wort, malt and hops.

- Mining industry aggregate, cement, gypsum, clinker, slurries, aluminum oxide, bauxite, iron ore, and Direct Reduce Iron (DRI)

Guided Radar for Overall Level, Oil Level and Water Level in Clear Interfaces

Sensor Fusion for Overall Level, Oil Level and Water Level in Clear & Emulsion Interfaces

Point Level or Limit Detection in Liquids

Point Level or Limit Detection in Solids